Easy to get started. Easy to finance. Reduced risk

Getting the most from your rotating equipment is about more than just monitoring and planning. It's about gaining new insights by deploying connected technologies that enable delivery of the right services and MRO spares at exactly the right time. Take five minutes to see what SKF can do to maximize your rotating equipment performance and lower your total cost of ownership at www.skf.com/REP

The key to success

Condition monitoring is the process of determining the condition of machinery while in operation. The key to a successful condition monitoring programme includes:- Knowing what to listen for

- How to interpret it

- When to put this knowledge to use

Successfully using this programme enables the repair of problem components prior to failure. Condition monitoring not only helps plant personnel reduce the possibility of catastrophic failure, but also allows them to order parts in advance, schedule manpower, and plan other repairs during the downtime.

PRODUCTS

The essential monitoring tools that no industrial manufacturing plant should be without.

View More >

Portable instruments enable the user to establish a comprehensive periodic condition monitoring programme.

View More >

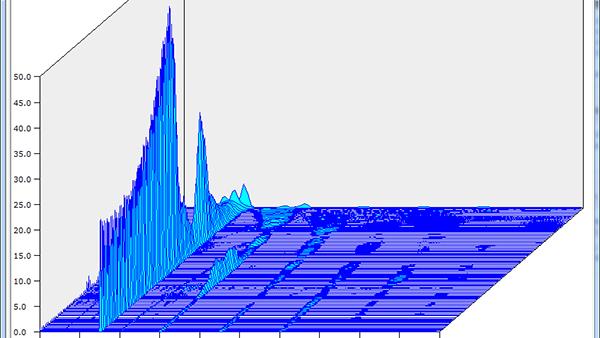

SKF has comprehensive software solutions with powerful diagnostic and analytical capabilities

View More >

As part of any product life-cycle, devices and systems reach a phase where they are no longer promoted

View More >